MIT Devises ‘Electroadhesive Stamp’ to Build Ultra-Complex Circuit Boards

If you’ve ever peeked inside a modern electronic gizmo, you know that circuit boards are getting deviously complex. You simply can’t rely on humans to assemble these devices anymore, but even robots are nearing their limits. Researchers at have developed a new technology that could help robots , and they call it an electroadhesive stamp.

Some modern devices contain chips and other components no wider than a human hair, and there’s still a drive to make circuit boards even denser. Robots can place these objects with incredible precision, but a traditional grasper can’t manipulate anything smaller than roughly 50-100 micrometers.

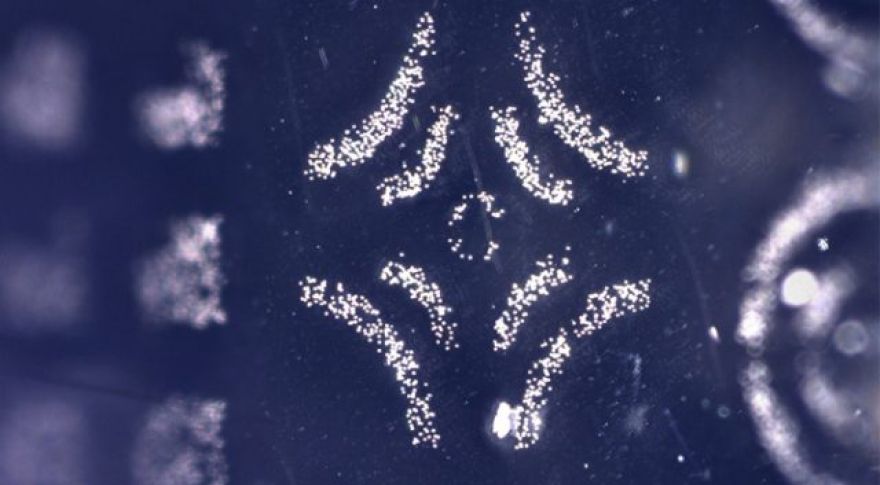

The electroadhesive stamp developed by MIT could allow a robot to pick up and set down a component as small as 20 nanometers. That’s about 1,000 times narrower than a human hair. The stamp uses a type of electroadhesion to grab hold of small objects with the aid of carbon nanotubes. You might remember those — they were everyone’s favorite advanced material until graphene came along. They’re still pretty useful here, though.

The nanotubes that make up the stamp are covered with a layer of aluminum oxide. Then applying voltage, the nanotubes become polarized. The positive charge at one end can induce the opposite polarization in nearby conductive materials. For example, a microscope electronic component. With the voltage on, the stamp picks up the component when they come in contact. When the team turns off the power, the stamp loses its stickiness, and the component drops off. The team likens this to scotch tape that you can turn on and off at will.

In laboratory testing, the electroadhesive stamp was able to pick up films of nanowires, micro-LEDs, and small clusters of metal or ceramic nanoparticles. These are all far too small for current robotic graspers to place on a circuit board. This is not the only potential fix for our robotic grasper issues, but it seems like a strong contender based on the early testing. This technology could eventually play a role in the construction of futuristic electronic devices with circuit diagrams that are impossible to manufacture right now.

Now read: